Internal jack up climbing hydraulic conrete placing boom

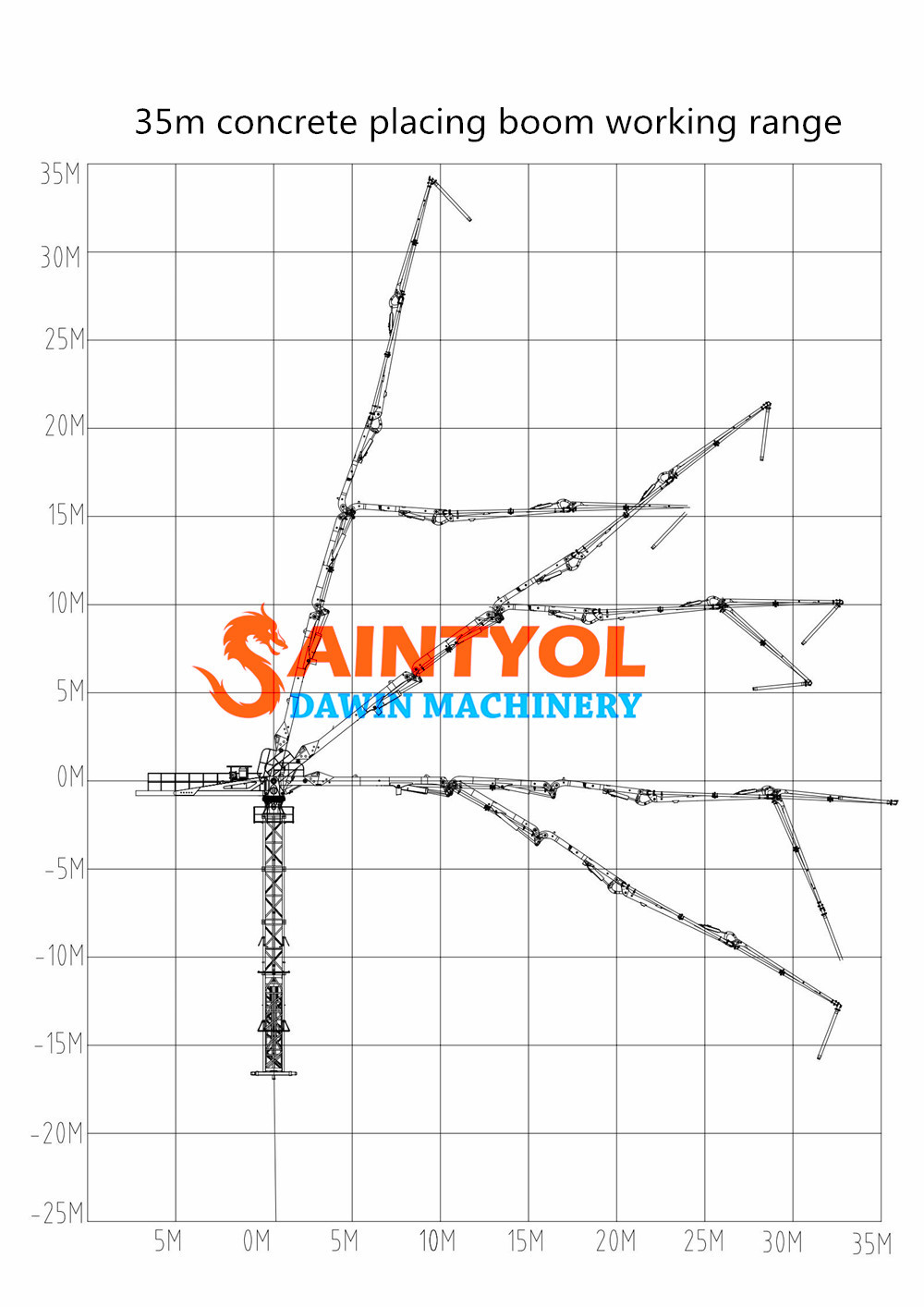

The concrete placing boom adopts a 360-degree full-rotation boom-type placing structure. The whole machine is easy to operate, flexible to rotate, and has the characteristics of high efficiency, energy saving, economy and practicality. Concrete placing machine is to expand the scope of concrete pouring.

The inner climbing distance of the jacking tower body is 3.6-5.2 meters, and the climbing mechanism is mainly composed of an inner climbing frame, telescopic outriggers and a jacking oil cylinder. The tower body under the standard configuration needs to be manually reset to the inner climbing frame, telescopic outriggers and jacking cylinders after each jacking is completed. If the tower body of the concrete placing machine is lengthened by a standard section, it can facilitate the distribution of different floor heights, reduce the frequency of jacking and transition, thereby reducing the labor intensity of workers, improving efficiency, and avoiding frequent assembly, disassembly, and handling.

The inner climbing distance of the truss tower body is 3.6-5.2 meters. There are two inner climbing methods to choose from: one is the traditional inner climbing structure, which requires manual disassembly and handling after each jacking is completed. Climbing ladders, etc.; the other is a new type of self-elevating inner climbing mechanism, whose working method is similar to the outer climbing method of independent tower cranes. labor intensity.

The climbing hydraulic placing boom in the elevator shaft is a type of hydraulic placing machine. The climbing hydraulic placing machine in the elevator shaft is equipped with an automatic climbing frame, which is lifted by the hydraulic cylinder and automatically climbs in the elevator shaft, so that the placing machine can rise with the floor. The rise has the following characteristics:

1. Use the elevator shaft space in the building to climb by yourself, and it will rise with the rise of the floor, and the process is simple and convenient;

2. According to different product models, there are two types of jacking structures: jacking rod and jacking frame;

3. Design different types of guide support structures according to the size of the elevator shaft on site;

4. It can meet the concrete pouring requirements of super high-rise working surface, and is not limited by height;

5. The lifting operation is very simple, scientific safety protection device, economical and efficient;

6. This type of distributor is mainly suitable for high-rise and super-high-rise buildings with shafts.