60m3/hr Trailer Concrete Pump With Diesel or Electric Power

Concrete Pump was a kind of useful and efficient concrete high pressure transport pump, widely used in highway, railway, bridge, building, tunnels, ports, water conservancy and other projects of grouting pressure, grouting mortar, concrete, large particle slurry grouting, spraying work, has the working pressure, pumping ability strong, grouting with high efficiency, smooth coating, using solid, etc.

Saintyol DAWIN Machinery Concrete pump design is light, easy to move, suitable for small and middle construction projects.

The S-valve series concrete pump is a new generation product developed by combining latest technologies both at home and abroad.

The products have passed ISO9001-2008 quality management system certification and CE certification.

Our workers strictly control all the machining processes and assembly quality, give final test to every pump by simulation working conditions and overload experiments to ensure customers zero fault as first operation.

DHBT60S-13-129 | Item | Units | technical data |

Whole Machine Performance | theoretical delivery volume | m³/h | 60 |

theoretical delivery pressure | M | 12.5 | |

Max. delivery frequency | Times/min | 22 | |

theoretical delivery height | m | 180 | |

theoretical delivery distance | m | 500 | |

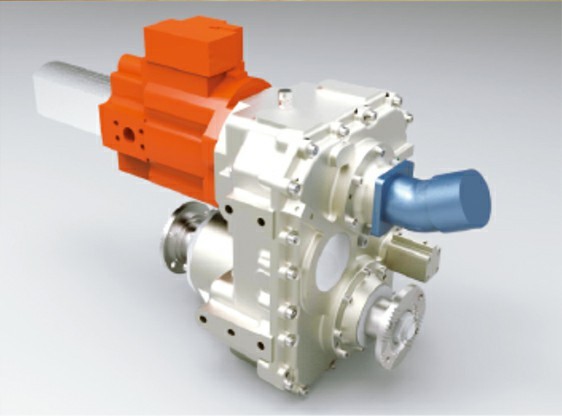

Type of distribution valve | S tube Valve | ||

Specification of delivery cylinder | mm | Φ200×1650 | |

Specification of main oil cylinder | mm | Φ125/Φ80×1650 | |

Oil tank capacity | L | 500 | |

Hopper capacity | L | 600 | |

Feeding height | mm | 1400 | |

Outlet diameters | mm | Φ185 | |

Delivery pipe inner diameter | mm | Φ125 | |

Power system | Diesel Power ( Deutz diesel engine) | Kw | 129 |

Rated rotate speed | r/min | 2300 | |

Idling speed | r/min | 800 | |

Voltage of battery cell | V | 24V | |

fuel tank capacity | L | 150 | |

Hydraulic system | Hydraulic oil circuit type | Open circuit | |

Max. oil pressure of main system | MPa | 32 | |

Max. oil pressure of mixing system | MPa | 14 | |

Max. mixing rotate speed | r/min | 24 | |

Other parameters | Concrete slump | mm | 80~200 |

Allowable max dia. of aggregate | mm | Pebble 50, crushed stone 40 | |

Dimension(length×width× height) | mm | 6600×1930×2190 | |

Weight | Kg | 6300 | |

Pulling speed | Km/h | ≤8 | |

Item | Unit | Parameter | ||

Pumping system | Max. theoretical delivery volume | m³/h | 60 | |

Max. theoretical delivery pressure | MPa | 12.5 | ||

Max. delivery frequency | times/min | 22 | ||

Distribution valve type | S tube valve | |||

Main oil cylinder specification: cylinder dia./pole dia.× journey | mm | Φ125/Φ80×1650 | ||

Concrete cylinder specification | mm | Φ200 | ||

Hopper capacity | L | 600 | ||

Output opening diameter | mm | 150 | ||

Hoisting height | mm | 1400 | ||

Power system | Main electric motor power | KW | 90 | |

Rated voltage | V (AC) | 380 | ||

Rated rotation speed | r/min | 1480 | ||

Hydraulic system | Type of Hydraulic oil circuit | Open circuit | ||

Main oil pump | Japanese Kawasaki | |||

Maximum system oil pressure | MPa | 32 | ||

Maximum oil pressure of mixing system | 14 | |||

Highest mixing rotate speed | r/min | 24 | ||

Hydraulic oil tank capacity | L | 420 | ||

Allowed max dia.of aggregate | Pebble50, crushed stone 40 | |||

Inner dia.of concrete delivery pipe | mm | Φ125 | ||

Max. delivery distance | horizontal | 700m | ||

vertical | 180m | |||

Dimension (length× width× height) | In transit | mm | 6170× 1800×2100 | |

Weight | kg | 5000 | ||

- Tel

- *Title

- *Content

Don't forget to sign up!

Find out early about all upcoming promotions and

newproducts releases

- Name:

- Michael Liu

- Tel:

0086-186-69798625

0086-532-89659612

- WhatsApp:

- https://wa.me/8618669798625

- Address:

- Office: 216# THE 308 STATE ROAD, CHENGYANG DISTRICT, QINGDAO SHANDONG,CHINA. Factory: No.413# Tieqishan Road, Yuhuangling Industrial Park, Chengyang District, Qingdao, China